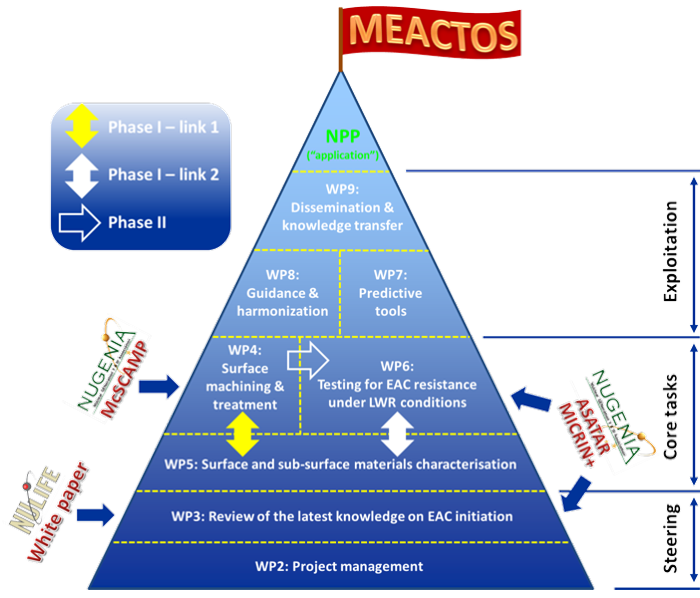

MEACTOS project outline

Mitigating Environmentally-Assisted Cracking Through Optimisation of Surface Condition – MEACTOS

Environmentally-assisted cracking (EAC) is one of the major failure modes occurring in light water reactors (LWRs). The condition of surfaces exposed to the primary coolant plays a major role on the susceptibility of components to EAC. However, many national and international guidelines and standards do not address surface condition of critical components in nuclear power plants (NPPs).

MEACTOS was proposed and conducted by a consortium of 16 partners from 11 EU member countries (Spain, France, Finland, Czech Republic, Belgium, Germany, Slovakia, Romania, UK, The Netherlands and Slovenia) plus Switzerland (associated country of Euratom/Horizon 2020), that comprises all the appropriate key players to ensure the availability of technologies, capabilities, technical and operational knowledge required for the goal of the project. Research laboratories (VTT, SCK CEN, CVR, CIEMAT, PSI, JRC, RATEN, ZAG), universities (UNIMAN, STUBA), nuclear component suppliers (NAMRC, ENSA), utilities (EdF), an engineering company (Jacobs) and plant designer (Framatome GmbH) have been selected in order to complete the required capacities covering all the expertise fields faced by the project. The consortium members have differential but complementary skills and expertise in areas such as project management, manufacturing, technology transfer or dissemination, to name a few key areas.

Pro-active material degradation programmes outside Europe, particularly in Japan and in the United States, currently address, or plan to address, surface condition with respect to EAC. This European MEACTOS project will directly benefit Europe, engaging on an equal footing with these initiatives, maintaining a level of competitiveness for European industry in the global scenario.

A more detailed description can be found under the “Project” menu item and please download the project flyer.